Last month we were graciously invited by our friends at Far West Rice to visit their milling facility. I was really excited about the trip, as my grandfather was a rice farmer in Taiwan. I also wanted my children to have the first-hand experience of how food arrives on the table as an educational learning experience for them.

Before I share the details of the trip, we want to thank Greg, Bill, Chris, Melanie and the rest of the Far West Rice family for an amazing day. My family and I had so much fun learning about rice farming and milling, and we look forward to visiting again. There are only fourteen rice mills in all of California, so we feel really lucky to have this wonderful experience.

Welcome to Rice Country.

Far West Rice is located in Nelson CA, about 30 minutes south of Chico. It is a family owned company specializing in the milling and marketing of high quality medium and short grain varieties. We immediately noticed how clean and organized the facility is when we arrived.

Our fun filled day started with Greg introducing us to the philosophy of Far West Rice: a high quality product with Just In Time milling, which differentiates them from rest of the larger millers. Chris then taught us about the basics of rice; he explained the difference between brown rice and white rice, and gave us a tour of their quality control process.

Later on in the day, we got to observe the entire milling process. In addition to their passion to deliver quality rice products, we learned that Far West Rice was also the first miller in the region to use solar power. Their panels cover four acres with 5,500 Photovoltaic Modules producing 821 kilowatts! It’s part of Far West Rice’s culture to promote a sustainable future.

Now, are you ready to see how rice is harvested and milled? Our stories are divided into 3 parts. Grab a cup of tea and sit back and enjoy the rice journey.

Harvesting:

Rice is planted in spring and is ready for harvest in the fall. Unlike Japan where rice is collected by smaller vehicles or sometimes by hands, here in the US, this huge combine harvests rice from the rice paddy very quickly.

Nami and the kids got to enjoy the ride and they said this huge vehicle is actually very comfortable inside.

The combine cuts and stores the rice on the back of the vehicle.

Once the combine is full, the rice is transferred to a tractor with a grain cart.

The rice is then transferred from the grain cart to a truck.

The truck delivers the rice to a drying and storage facility, such as BUCRA below.

Quality Testing & Milling:

When the rice is ready to be milled, the truck picks up the rice from storage and delivers to the rice mill. The truck makes its first stop at the milling plant where a sample of the rice is collected at the entrance.

At Far West Rice, the quality of the product is of utmost importance. After the sample of rice is collected by the long metal straw, it is then put through several tests.

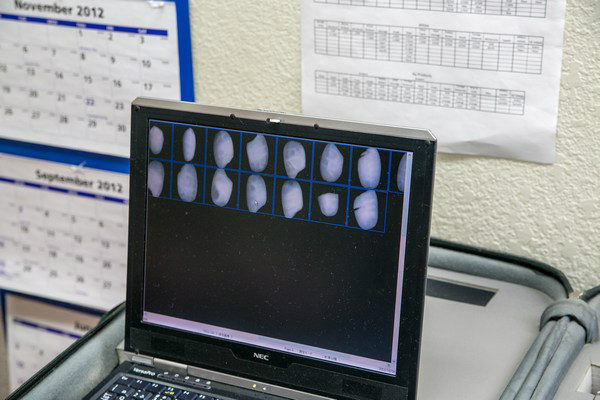

Each batch of rice that arrives undergoes a moisture content test. The correct moisture percentage is extremely important as the rice goes through the milling process. As part of quality control, each batch also goes through a mini-milling process in the quality lab so a snapshot of the final product can be produced.

Each batch of rice is carefully cataloged and inventoried.

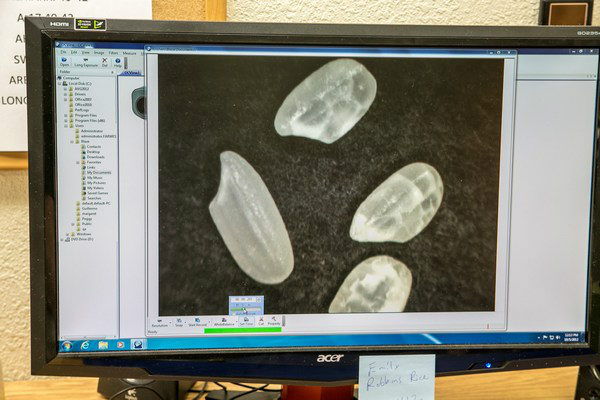

As part of the quality process, the samples are checked for cracks.

You can see very clearly what good rice looks like when compared to cracked rice kernels.

Following the quality testing process, cook tests are also performed. After all, our taste buds are the best test!

After the truck is done with sampling, it enters the milling facility. The truck then drops the rice into intake pit. The rice then rides the elevator to top of the milling plant and starts its journey.

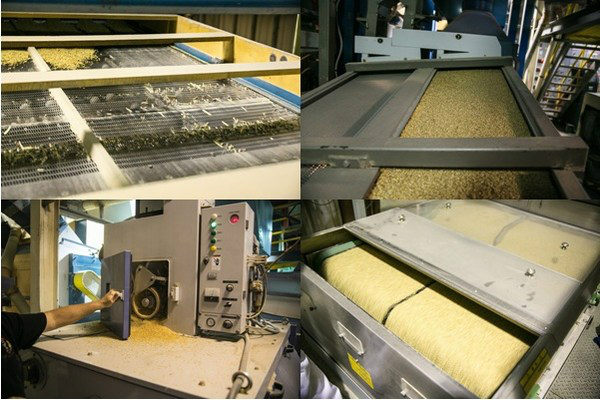

The paddy first goes through a machine to remove the hull (shell). After the shells are removed, the brown rice is sent through a magnetic machine to remove any stones.

The brown rice then goes through three separate polishing machines; each one is set to a different setting. Unlike other large millers, Far West Rice is able to mill different types of rice, depending on the customer’s needs. Large millers tend to mill only one type of rice for a fixed amount of time.

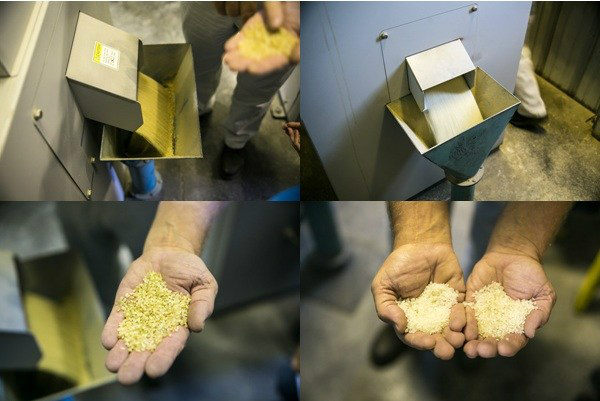

The milled rice goes through a sifter and length grader so the final product is the same size. If the rice does not meet the specifications, it goes to the rejected bin.

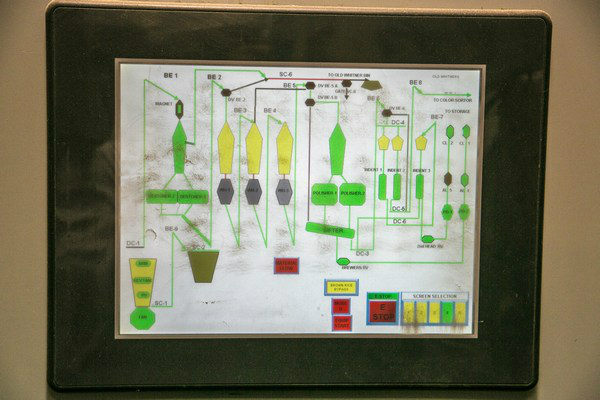

This is the control panel for all the machines.

The final quality check is done by camera. Any rice not meeting the specifications is rejected by a blast of air (scanned by camera).

Rice is milled and ready to be packed. This is the first batch of Koshihikari in 2012.

The final product is again sampled for quality control, then bagged and sent for shipment.

The turnaround time at Far West Rice is usually 24 hours from delivery to shipping, ensuring the highest quality products are produced.

Japanese Rice – Most Fundamental Food

There is a long history of rice being cultivated in Japan for over 2000 years. It is by far the most fundamental food in Japanese cuisine that the word for it “gohan” also means the “meal” itself.

Japanese rice is a thin and fat short-grain rice, and also known as japonica, uruchimai, or sushi rice (not vinegared sushi rice used for sushi). When cooked properly, the rice grains cling together without being mushy.

We received several kinds of rice from Far West Rice and one of them was Komachi, their finest California Supreme Short Grain Rice. Far West Rice provides their customers the freshest rice by milling only when they receive an order.

Before Melanie from Far West Rice sent us a bag of freshly milled rice, I never knew that freshly milled rice tastes so much better than rice that’s been sitting in the store for a while. The fragrance of the freshly milled rice and the softness of the texture really stand out compared to regular rice.

We have a Zojirushi Induction Rice Cooker and typically for 3 cups of Koshihikari rice we need to add water to the 3.5 cup water mark (3 cup is a little too hard for our liking). With freshly milled rice, we actually reduce the water to below 3 cup water mark and it comes out perfect.

You can purchase Komachi on Amazon.

Thank you again Far West Rice!

Useful (?) Manners When Eating Rice in Japan

- You must hold your rice bowl with your hand while eating from it.

- It is considered as a polite manner to finish every single grain of rice in a bowl as a way of appreciating rice farmers.

- Never leave your chopsticks standing up vertically in your rice – it’s used for funerals (resembles burning incense).

Bonus Family Album

Here are some pictures of my family during the tour…

Un turneu minunat,toate explicatiile sunt bune si in detaliu. Multumesc mult Nami.

Hi Lacramioara,

So happy you enjoyed our tour of the rice milling facility. It’s good to know how your food is processed.

Great reporting Nami, looks like an interesting look inside Far West Rice;-). I’ve driven through this area and remember seeing the miles of rice fields, so peaceful and beautiful to see! It good to take a moment to appreciate where our food comes from;-)

This is so cool! I would love to go and see everything that goes behind closed doors in rice fields to get to our packaged rice in stores. How interesting that freshly milled rice tastes so much better than rice in stores – I had no idea! Really want to try some now but no idea where to get it lol

What a terrific experience! You must have had a wonderful day. I learned so much – thanks for the great description and wonderful pictures. Now I know I need to find some freshly milled rice! Thanks so much.

What an interesting post and I am sure your kids love the outing and gained so much knowledge in a fun way!

Thanks for sharing the “rice field” experience!

Just recently, I heard a conversation about the 1000+ yr-old rice terraces in the Philippines and hope I can see that for myself one day.

what an amazing story and amazing way of putting it into words. I love the tour- it was top notch it seems! I grew up with our 3rd generation rice, corn, soybean and wheat farm and always count my blessings that I was apart of something so valuable to our economy.

広い大地に囲まれて、豊かな土地で育まれて伸びるお米さんたち、、、映画の中に出てきそうなシーンですね。

ところで、お米はただでもらえたかい?楽しい感謝祭になりますようね。

I had a chance to drive a tractor once but would bribe someone to let me drive a combine like this one. Your children are lucky that they can attend trips like this one.

Very informative post Nami! Thanks for sharing your experience with us!

How amazing that sometimes here in the west, all we see is the bowl of rice on the dinner table and one might say “rice is a rice.” What we don’t know is the long process of getting those rice on the dinner table. Another thing that amazes me is the difference of processing between a developed country like the U.S. and some Asian countries like where I came from. Here we used technology and there, they used back-breaking human technology. Thank you so much for sharing this post Shen and Nami — This is very educational. I wish you guys and the kids a wonderful Thanksgiving!

~ ray ~

Really wonderful experience. I would definitely take my kids there for a visit so they can learn where the rice they eat are actually from (not the market, haha…)